Centrifugal Oil Separator Documentations, Technical Document

Principle of forming a centrifugal separation

1. Principle of separation of solids from liquids

| As we know, if we want to remove solid particles from a liquid (e.g. fuel), we can put the mixture of liquid and solid into a vessel. Solid particles mixed in the liquid will tend to settle to the bottom of the vessel thanks to the difference in density of the solid compared to the liquid. |  |

| Once all the solid particles have completely settled to the bottom of the vessel, we can pour the clean liquid above into another container. However, the time to completely separate this amount of solids from the liquid depends entirely on the settling speed of the solids and the density difference between the liquid and the solid. Solids with higher specific gravity will settle faster and vice versa. |  |

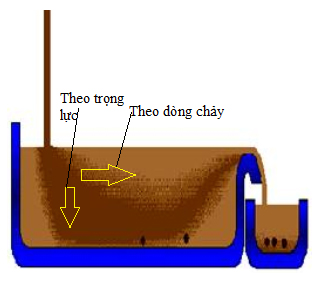

| Solid particles inside the vessel will have two movement trends: both settling to the bottom of the vessel and moving with the flow. Therefore, when we increase the flow speed, small suspended solid particles that have not yet settled will tend to flow out of the clean fuel vessel. |  |

2. Principle of separation of two liquids

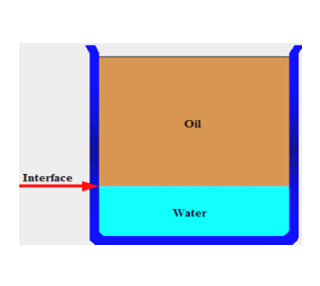

| When we put the mixture of water and oil in a vessel. Due to the difference in density between the two liquids, oil will occupy the upper volume while water occupies the lower volume. Thus, an interface will form between the two liquid layers, which we call the neutral surface. |  |

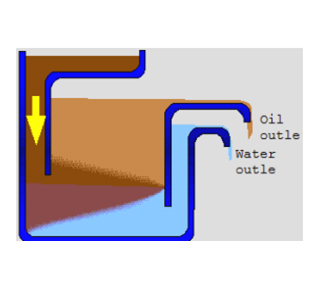

| If we have a vessel shaped like the illustration, when the above mixture is added, a neutral surface will also form. At this time, the oil will escape from the oil outlet and the water will escape from the water outlet. |  |

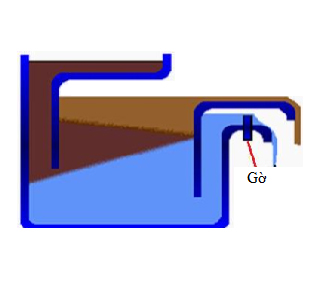

| If we add a berm as shown in the illustration, the berm will now act as a spillway. If the burr is high, the neutral surface will move up and water can escape through the oil line. On the contrary, if a low berm is installed, the oil can escape through the water line. |  |

3. Operating principle of centrifugal separator

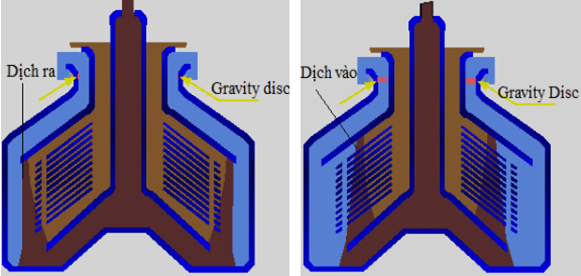

The centrifugal separator is designed on the basis of the above two principles. Similar to the berm on the vessel, a gravity disc is designed at the water outlet path.

If the inner diameter of this disc is large, then the neutral surface will move outside the center of the drum similar to the case of placing a low berm. If the inner diameter of the disc is small, the neutral surface will move to the center of the drum, similar to the case of placing a high berm.

4. Groups of centrifugal separators

Current centrifugal separators are classified into two main groups: Conical disc centrifugal separators and tube centrifugal separators.

With conical disc centrifugal separators, the separator core consists of truncated conical discs stacked on top of each other to form a disc bundle. The centrifugal separation process takes place in the disk bundle space.

With a tube centrifugal separator, dirty oil is fed into a cylindrical rotating tube. When the tube rotates, dirty oil also rotates with the tube and is affected by extremely large centrifugal force.

In both types of separators, the sediment with the highest density will settle on the drum wall. Water with a lower density will occupy the second layer in the drum, while clean oil with the lowest density will occupy the innermost layer.

Dirty oil is continuously fed into the drum, and clean oil and water (depending on separation mode) are also continuously removed while the remaining dirt is periodically flushed out.

The conical disc centrifugal separator group can be classified into different types depending on their structure, working principle, and function in the oil treatment system.